long eaton sofas

Great British Craftsmanship

Long Eaton is the UK Centre of Excellence in Upholstery Manufacturing and furniture made here is hand-made by highly skilled, time served craftsmen and women.

Every piece of furniture is handmade in our Long Eaton factory.

Most upholstery now sold in the UK is sadly either imported, or if it is made in the UK, it is more than likely mass-produced.

Fabrics and leather are cut in piles with automated cutting machines and upholstery is done on a flow-line or track system. Therefore, no operative is responsible for the final quality of the build except an inspector at the end of the line.

At Long Eaton Sofas, every piece of furniture is handmade in our Long Eaton factory and is inspected at every stage of manufacture to ensure you receive the highest quality finish possible.

Our construction

Our frames are made by us in our own wood mill, which enables us to make our furniture to bespoke sizes if required.

All frames are hand-built using seasoned kiln-dried beech, or birch hardwood from Europe, typically from Scandinavia, or the Baltic States.

Skilled wood machinists mill the frame parts, before an experienced framemaker builds the frame. All joints are glued, screwed and dowelled for strength. Separate corner blocks are used to support the legs, or feet and all spring rails are supported by 15, or 18cm solid wooden blocks.

The whole process ensures that our frames are built to last and as such, we give a 30 year construction guarantee on them.

A short video showing our skilled craftspeople manufacturing our solid hardwood frames.

Watch

Cutting & sewing

Our fabric cutters are highly skilled and can turn any fabric, no matter how complicated the design, into a perfectly matched piece of furniture.

Fabrics are marked out and cut by hand to ensure that any weaving and printing faults are avoided. Leather is also marked out and cut by hand to ensure scars and growth marks are avoided wherever possible.

Once the fabrics and leathers are cut, they move on to our sewing department where they are sewn by one of our skilled machinists, each of which have been with the company since the year we started.

A short video showing the skill and expertise of our Cutting & Sewing Department

Watch

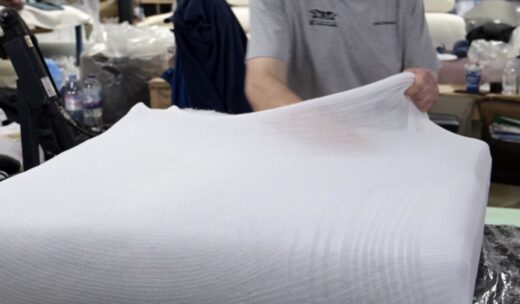

Upholstery

Each piece of furniture is hand-made by one of our skilled upholsterers, who makes the whole piece from start to finish and is individually responsible for its quality and finish. Once completed, each piece is proudly hand-signed by the craftsman who made it.

A short video showing the care and attention our skilled upholsterers take when manufacturing our handmade upholstery.

Watch

Cushion fillings

We offer our customers a wide range of cushion interior options to get the comfort just right. Seat cushions are available in foam, hollow fibre and feather.

We have two standard seat grades of foam, but we can also order softer, or firmer grades from our cushion supplier if necessary.

DACRON® Quallofil® Blue is the eco-friendly choice for furniture cushions and is used in our polyester hollow fibre seat and back cushion interiors.

Quallofil® Blue is a new polyester fibre for sustainable sofa cushions. The filling fibre is made from 100% recycled bottles, of which 50% is Prevented Ocean PlasticTM collected from coastlines at risk of ocean plastic pollution. The Prevented Ocean PlasticTM programme is a global recycling initiative which helps tens of thousands of people around the world to earn their living, clean their coastlines and prevent ocean plastic.

Plastic waste is collected before it enters the oceans and rivers in regions that do not have efficient and formal waste or recycling systems. The collected plastic is then washed, crushed, and dried, becoming strictly controlled PET flakes. This is used by ADVANSA in a 50% blend as a valuable raw material in the manufacture of polyester filling fibres. ADVANSA fibres are GRS (Global Recycled Standard) independently certified and audited for traceability.

High technology Quallofil® Blue cushions will not only last a long time and maintain its original appearance, but by choosing this filling for your sofa cushions, you are also helping the planet at the same time!

Octo-Core: Revolutionizing Sofa Comfort

One of the most common concerns among sofa owners is the constant need to plump cushions. We understand that maintaining a perfectly styled sofa isn't always a priority in busy daily life.

Traditional feather cushions with a foam core were designed to address this issue and are being used by some furniture retailers now. They often fall short, sometimes feeling too firm or revealing the rigid foam core, diminishing the overall comfort.

Introducing Octo-Core, a breakthrough in cushion technology. Utilizing Podz foam airflow technology, widely recognised in the mattress industry, our supplier has engineered a luxurious, responsive and long lasting cushion. The Podz system functions like foam shaped springs, compressing gently under weight for superior comfort and rebounding instantly to maintain a plush, inviting appearance. Additionally, the airflow created by the Podz structure enhances feather aeration, ensuring cushions remain fresh and full.

The Octo-Core is available in two cushion interiors:

Octo-Core Fibre A Podz foam core that is then encased in a premium 750g fibre filling. The perfect cushion for any customer with a feather allergy or wants a lower maintenance seat cushion.

Octo-Core Feather A Podz foam core with a premium duck feather jacket. The perfect balance of softness and support for a truly elevated seating experience.

In some models, you can also have the option of 100% duck feather seat cushions.

Back cushion interiors are available in Quallofil® Blue, or 100% duck feather.

A short video showing how we manufacture our cushion interiors

Watch

Get the latest inspiration and offers.

Sign up to our newsletter to be the first to hear about our latest news, inspiration, offers and promotions.

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.